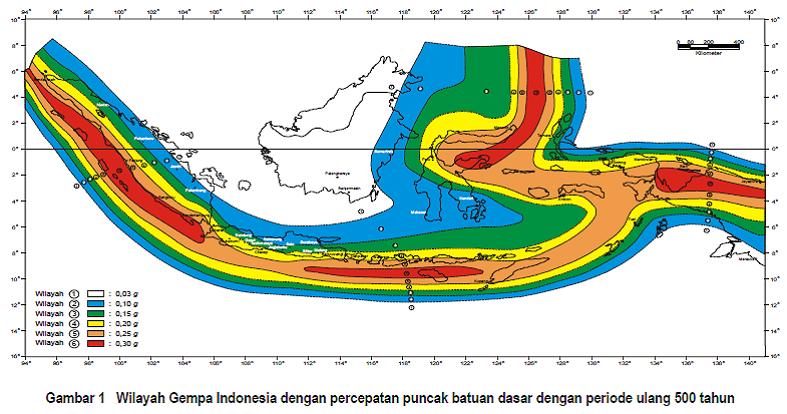

Base Isolation: Origins and Development

James M. Kelly

Professor Emeritus Civil and Environmental Engineering

University of California, Berkeley

Research at EERC

Research on the development of natural rubber bearings for isolating buildings from earthquakes began in 1976 at the Earthquake Engineering Research Center (EERC) (now PEER, the Pacific Engineering Research Center) of the University of California at Berkeley. The initial research program was a joint effort by EERC and the Malaysian Rubber Producers Research Association (MRPRA), U.K. The program was funded by MRPRA through a number of grants over several years, with later funding provided by the National Science Foundation and the Electric Power Research Institute. Professor James M. Kelly directed the research at EERC, which included considerable theoretical and experimental contributions by graduate students.

Although not an entirely new idea at the time—a few methods using rollers or sliders had been proposed—the concept of base isolation was considered to be very impractical by most of the structural engineering profession. The research project began with a set of hand-made bearings of extremely low-modulus rubber used with a simple three-story, single-bay, 20-ton model. Shaking table tests showed that isolation bearings could bring about reductions in acceleration by factors of as much as ten when compared to those of conventional design and that, as predicted, the model would respond as a rigid body with all deformation concentrated in the isolation system. It was also clear that a certain degree of damping was needed in the system and that the scale of the model was too small to allow more practical rubber compounds to be used.

In 1978, a more convincing demonstration of the isolation concept was achieved with a more realistic five-story, three-bay model weighing 40 tons and by using damping-enhanced bearings made by commercial techniques. A strong interest throughout the EERC research program was in the influence of isolation on the response of equipment and contents in a structure, which tend to sustain more damage when conventional methods of seismic-resistant design are used and which, in many buildings, are much more costly than the structure itself. An extensive series of tests on the five-story frame demonstrated that isolation with rubber bearings could provide very substantial reductions in the accelerations experienced by internal equipment, exceeding the reductions experienced by the structure. However, the same tests showed that when additional elements (such as steel energy-absorbing devices, frictional systems, or lead plugs in the bearings) were added to the isolation system to increase damping, the reductions in acceleration to the equipment were not achieved because the added elements also induced responses in the higher modes of the structure, affecting the equipment. It became clear that the optimum method of increasing damping was to provide it in the rubber compound itself. This method was applied later in the compound developed by MRPRA and used in the first base-isolated building in the United States, described below.

Rubber bearings are relatively easy to manufacture, have no moving parts, are unaffected by time, and are very resistant to environmental degradation.

Test of bearing used in the Indonesian demonstration building. Photo: I. D. Aiken

Test of bearing used in the Indonesian demonstration building. Photo: I. D. Aiken

The bearings are made by vulcanization bonding of sheets of rubber to thin steel reinforcing plates. Because the bearings are very stiff in the vertical direction and very flexible in the horizontal direction, under seismic loading the bearing layer isolates the building from the horizontal components of the ground movement while the vertical components are transmitted to the structure relatively unchanged. Although vertical accelerations do not affect most buildings, the bearings also isolate the building from unwanted high-frequency vertical vibrations produced by underground railways and local traffic. Rubber bearings are suitable for stiff buildings up to seven stories in height. For this type of building, uplift on the bearings will not occur and wind load will be unimportant.

U.S. Applications

The first base-isolated building in the United States is the Foothill Communities Law and Justice Center, a $30 million legal services center in Rancho Cucamonga San Bernardino County, about 97 km (60 miles) east of downtown Los Angeles. Completed in 1985, the building is four stories high with a full basement and sub-basement for the isolation system, which consists of 98 isolators of multilayered natural rubber bearings reinforced with steel plates. The superstructure of the building has a structural steel frame stiffened by braced frames in some bays.

Foothill Communities Law and Justice Center. Photo: I. D. Aiken.

Foothill Communities Law and Justice Center. Photo: I. D. Aiken.

The building is located 20 km (12 miles) from the San Andreas fault. San Bernardino County, the first in the U.S. to have a thorough earthquake preparedness program, asked that the building be designed for a Richter magnitude 8.3 earthquake, the maximum credible earthquake for that site. The design selected for the isolation system, which accounted for possible torsion, incorporated a maximum horizontal displacement demand of 380 mm (15 in.) in the isolators at the corners of the building. Tests of full-scale sample bearings verified this capacity.

The highly filled natural rubber from which the isolators are made, developed as part of the EERC research program, has mechanical properties that make it ideal for a base isolation system. The shear stiffness of this rubber is high for small strains but decreases by a factor of about four or five as the strain increases, reaching a minimum value at a shear strain of 50 percent. For strains greater than 100 percent, the stiffness begins to increase again, providing a fail-safe action under a very high load. The damping follows the same pattern but less dramatically, decreasing from an initial value of 20 percent to a minimum of 10 percent and then increasing again. The design of the system assumes minimum values of stiffness and damping and a linear response. The high initial stiffness is invoked only for wind load design and the large strain response only for fail-safe action.

This high-damping rubber system was also adopted for the Fire Department Command and Control Facility (FCCF) of Los Angeles County, completed in 1990. (The same type of high-damping rubber bearing was also used for the Italian telephone company, S.I.P., Ancona, Italy, the first modern base-isolated building in Europe.) The FCCF building houses the computer systems for the emergency services of the county and is therefore required to remain functional after an extreme event.

Fire Department Command and Control Facility. Photo: I.D. Aiken

Fire Department Command and Control Facility. Photo: I.D. Aiken

The decision to use base isolation for this project was reached by comparing conventional and isolation schemes designed to provide the same degree of protection. In most projects, the isolation design costs five percent more. Not only was the isolation design estimate 6 percent less in this case but is less for any building when equivalent levels of protection are considered. Furthermore, these costs are first costs. Life-cycle costs are even more favorable. Also noteworthy is that the conventional code design requires only a minimal level of protection, that the structure not collapse; whereas isolation design provides a higher level of protection.

The University of Southern California Teaching Hospital in eastern Los Angeles is an eight-story concentrically braced steel frame supported on 68 lead rubber isolators and 81 elastomeric isolators. The building was instrumented by the California Strong Motion Instrumentation Program soon after its completion in 1991. The foundation system consists of spread footings and grade beams on rock. Because of functional requirements, both the building plan and elevation are highly irregular with numerous setbacks over the height. Two wings at either side of the building are connected through what is referred to as the "necked-down" portion of the building, and in the original fixed-base design the irregular configuration led to both coupling between the lateral and torsional vibration modes and very large shear force demands in the slender region between the two rings. (Even in the isolated design steel trusses are required to carry the shears in the necked-down region.) These were two of the main reasons that seismic isolation was eventually chosen for this structure.

University of Southern California University Hospital. Photo: P. W. Clark.

University of Southern California University Hospital. Photo: P. W. Clark.

The University of Southern California (USC) Teaching hospital was 36 km (23 miles) from the epicenter of the Mw 6.8 1994 Northridge earthquake. The peak ground acceleration outside the building was 0.49 g, and the accelerations inside the building were around 0.10 to 0.13 g. In this earthquake the structure was effectively isolated from ground motions strong enough to cause significant damage to other buildings in the medical center. The records obtained from the USC hospital are particularly encouraging in that they represent the most severe test of an isolated building to date.

Nuclear Applications

Isolation used in conventional nuclear plants greatly simplifies the expensive and time-consuming design and qualification of the equipment, piping, and supports for seismic loading. In addition, when seismic design criteria are increased due to the discovery of nearby faults, for example, the plant need not be redesigned; upgrading the isolation system is sufficient.

In an experimental program at EERC isolation bearings were designed, produced, and tested for two types of liquid metal reactor designs. The first, called PRISM, uses high-shape factor isolation bearings designed to provide horizontal isolation only. In the other design, SAFR, the reactor is supported on low-shape bearings that provide both horizontal and vertical isolation. The results of this test series extended the range of the isolator types with well-understood characteristics.

Base Isolation in Japan

After a slow start, base isolation research and development in Japan increased rapidly. The first large base-isolated building was completed in 1986. Although such buildings in Japan require special approval from the Ministry of Construction, as of June 30, 1998, 550 base-isolated buildings had been approved.

Base isolation has advanced rapidly in Japan for several reasons. The expenditure for research and development in engineering is high with a significant amount designated specifically for base isolation; the large construction companies aggressively market the technology; the approval process for constructing a base-isolated building is a straightforward and standardized process; and the high seismicity of Japan encourages the Japanese to favor the long-term benefits of life safety and building life-cycle costs when making seismic design decisions.

The system most commonly used in the past has been natural rubber bearings with mechanical dampers or lead-rubber bearings. Recently, however, there has been an increasing use of high-damping natural rubber isolators. There are now several large buildings that use these high-damping bearings: an outstanding example is the computer center for the Tohoku Electric Power Company in Sendai, Miyako Province.

Tohoku Electric Power Company, Japan. Photo: P. W. Clark

Tohoku Electric Power Company, Japan. Photo: P. W. Clark Currently the largest base-isolated building in the world is the West Japan Postal Computer Center, located in Sanda, Kobe Prefecture. This six-story, 47,000 m square (500,000 ft square) structure is supported on 120 elastomeric isolators with a number of additional steel and lead dampers. The building, which has an isolated period of 3.9 sec, is located approximately 30 km (19 miles) from the epicenter of the 1995 Hyogoken Nanbu (Kobe) earthquake, and experienced severe ground motion. The peak ground acceleration under the isolators was 400 cm/sec square (0.41 g) but was reduced by the isolation system to 127 cm/sec square (0.13 g) at the sixth floor. The estimate of the displacement of the isolators is around 12 cm (4.8 in.). A fixed-base building adjacent to the computer center experienced some damage, but there was no damage to the isolated building.

The use of isolation in Japan continues to increase, especially in the aftermath of the Kobe earthquake. As a result of superior performance of the West Japan Postal Computer Center, there has been a rapid increase in the number of permits for base-isolated buildings, including many apartments and condominiums.

Summary

Ongoing research has improved the effectiveness of isolators in decreasing problems of stability, roll-out, failure of the isolators, or unexpected response and the trend away from add-on mechanical dampers. Additionally, the difficulties of manufacturing large isolators have diminished. It is now possible to make bearings as large as 60 in. (1.5 m) in diameter. The 70 natural rubber bearings built for the M.L. King/C.R. Diagnostics Trauma Center in Willowbrook, California, were at the time of their manufacture the largest isolation bearings in the U.S. The isolators are 1.0 m (40 in.) in diameter. The combination of increased size with low-modulus rubber has resulted in highly reliable isolation systems.

There are several local applications of seismic isolation systems. The Oakland City Hall was retrofitted after the 1989 Loma Prieta, California, earthquake with about 110 large isolators. A new public safety building for Berkeley is now under construction and will use seismic isolators. The Martin Luther King Jr. Civic Center Building in Berkeley will be retrofitted using isolation, as will the Hearst Memorial Mining Building on the University of California at Berkeley campus. The classic Beaux Arts architecture and interior fixtures will be untouched by the retrofitting process, while the seismic resistance will be substantially enhanced.

To date 45 base-isolated buildings in the U.S. are planned, under construction, or completed—for new construction and for retrofitting. The use of base isolation applications up to this time in the U.S. has been for structures with critical or expensive contents, but there is increasing interest in applying this technology to public housing, schools, and hospitals in developing countries, where the replacement cost due to earthquake damage can be a significant part of the gross national product. The cooperation between EERC and MRPRA led to a new joint effort supported by the United Nations Industrial Development Organization (UNIDO) that developed low-cost isolation systems for such countries, and several demonstration projects are in place in Indonesia, the People's Republic of China, and Armenia. The research program at EERC, initially supported by MRPRA, was instrumental in making the base isolation approach to earthquake-resistant design a reality.

This paper is an update of “Base Isolation: Origins and Development,” EERC News, Vol. 12, No. 1, January 1991.

Seismic testing equipment at the Energy Technology Engineering Center in California.

Seismic testing equipment at the Energy Technology Engineering Center in California.

Inter-story drift is reduced by a factor of approximately two with the installation of energy dissipaters.

Inter-story drift is reduced by a factor of approximately two with the installation of energy dissipaters. The deformation pattern of an isolated structure during an earthquake. Movement takes place at the level of the isolators. Floor accelerations are low; the building, its occupants and loose contents are safe.

The deformation pattern of an isolated structure during an earthquake. Movement takes place at the level of the isolators. Floor accelerations are low; the building, its occupants and loose contents are safe.

Test of bearing used in the Indonesian demonstration building. Photo: I. D. Aiken

Test of bearing used in the Indonesian demonstration building. Photo: I. D. Aiken  Foothill Communities Law and Justice Center. Photo: I. D. Aiken.

Foothill Communities Law and Justice Center. Photo: I. D. Aiken.  Fire Department Command and Control Facility. Photo: I.D. Aiken

Fire Department Command and Control Facility. Photo: I.D. Aiken  University of Southern California University Hospital. Photo: P. W. Clark.

University of Southern California University Hospital. Photo: P. W. Clark.  Tohoku Electric Power Company, Japan. Photo: P. W. Clark

Tohoku Electric Power Company, Japan. Photo: P. W. Clark